The semi-automatic cap sealing machine is preciseness designed on a durable welded steel frame utterly enclose in stainless steel sheet and doors area unit provided to facilitate the servicing of the machine. The machine is having a motorized rotating head mechanism, which ensures correct cap protection with uniform torsion.

Require manually feeding & unloading the container, wherever the body and also the neck of the container area unit positioned below the rotating head, and sealing head is acting good operation of capping with uniform torque.

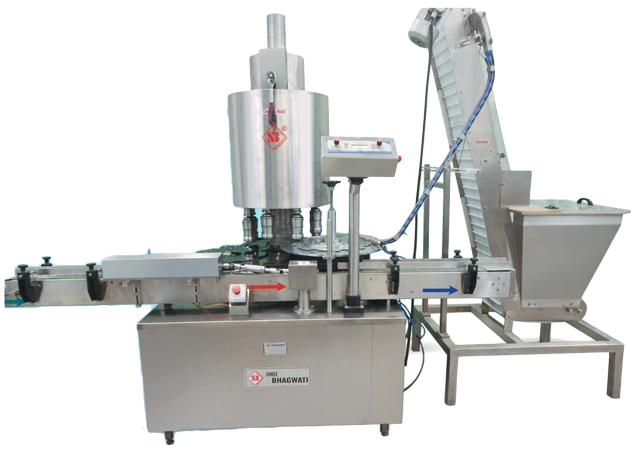

Jar / Bottle screw capping machine similarly well know chuck capper / rotary capper machines are flexible, self-supported on stainless steel leg with height adjustable adjustment system. The machine is preciseness designed on a durable welded steel frame utterly enclose in stainless steel sheet and doors area unit provided to facilitate the servicing of the machine.

The feed container moving on conveyer area unit feeds into an in-feed star wheel through in-feed worm, star wheel delivery the container below the Sealing head within the subsequent indexing part, in the meantime the bottle devour a cap from the delivery chute of cap filling bowl, wherever the body and also the neck of the container area unit positioned below the rotating head, wherever the Sealing head is acting good operation of threading & protection.

Our semi-automatic screw capping machine could be an automatic line screw capping machine that is integrated with a cap vibrator for cap orientation, vibrator hopper, and chute and capping station. This semi-automatic screw capping machine is widely employed in totally different producing lines for packaging and capping of bottles. The caps area unit tightened through a magnetic clutch operated capping head at terribly high speed so the capped bottles created their resolution through exit conveyor. The speed of this machine is often adjusted through the speed pot that is provided on a switch box. This semi-automatic screw capping machine has ss 304 body and 12feet long and 150mm wide conveyor.

As we all know the food business is growing very rapidly thus because of this reason the market of semi-automatic capping machines is additionally increasing with a vital rate. These days storing liquid or the rest could be a troublesome job, for protecting this we tend to use semi-automated capping machines and that we protect this by seal pack capping. There is a unit several challenges during this market like bottles and caps materials, styles aren't aligned in a very systematic manner. Several caps use paper, plastic or composite liners to produce the seal between cap and bottle. This causes 2 problems: initial, the liner less cap won't seal properly.

The liner, mixed with the caps will cause jams, particularly within the cap feeding chute. Cap placement is extremely vital for sturdy protection. Bottle holding is extremely essential whereas the capping method goes on. Capping review system ought to be correct that the protection of head covers is powerful. Globally Canada is predicted to be the most important marketplace for cap applicators on account of ample opportunities provided by the region to packaging machinery makers.We are a leading screw capping machine manufacturers who will provide the most effective to you with the proper product to serve you best. The semi-automated capping machine market is in the mature condition in Canada. In European countries like Spain, Germany, France, Italy, and in the United Kingdom, there are big possibilities for the growth of this industry. In developing countries like Asian countries, China, Brazil, Argentina, Mexico, there's a lot of chance of growing this market. In the Middle East and African countries, this semi-automated market is not in very good-excellent condition, thus there is a big significant possibility of growing.

Capping- Semi Auto Version

- Semi Auto Single Head ROPP Capper

- Semi Auto Single Head Screw Capper

- Semi Auto Crimper

Capping machine with Auto Version

- Single Head ROPP Capper

- Single Head Screw Capper

- Multi Head ROPP Capper

- Multi Head Screw Capper

- Mutli Head ROPP Cum Screw Capper

- Mutli Head Crimper

- Multi Head Plugger

- capping machine installed automatic filling line with different product and shape, Capping Unit, Magnetic Screw Capping Head with Mechanical Torque Adjustment; Caps Feeding, Vibratory Bowl Feeder; Cap Placement, Either Neck & Place or Pick.

- The Pick and Place (P&P) is an automatic Pick and Place Capper designed to automatically pick, place, and torque caps for PET, PVC, and glass bottles.