Tablet Counting & Filling Line - Manufacturer, Supplier, Exporter

Description

Apple Pack is leading Tablet Counting Machine and Capsule Counting Machine manufacturer specialized in Tablet Counting Machine, Tablet Counting Line, Capsule Counting Line, Capsule Counting Machine, Bottle Unscrambling Machine, Labeling Machine Manufacturer, Desiccant Inserting Machine, Cotton Inserting Machine, Capping Machine Manufacturer, Leaflet Outserter, Blister Packing Machine, and Capsule Filler Manufacturer , Desiccant Inserting Machine, Cotton Inserting Machine, Capping Machine Manufacturer, Leaflet Outserter, Blister Packing Machine, Capsule Filler Manufacturer

Apple Pack high volume off-shore (ISO 9001- 2000 & CE Certified) manufacturing makes it possible to provide their customers with the finest and most reliable packaging systems combined with local service. Apple Pack offers total responsibility for installation, training and on-going service. Please send us your inquiry today regarding our Tablet Counting Machine, Capsule Counting Machine, Tablet Counting Line, and other products

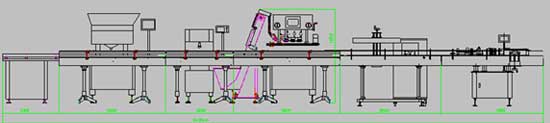

Automatic Tablet / Capsule Counting & Filling Line

Tablet Counting and Filling Machines?

Aside from the pharmaceutical industry, you can as well require the services of this machinery in the following sectors.

- Food Industry

- Health care sector

- Chemical Engineering

Let’s have a little discussion about each.

· Food industry

Recently, there is full acceptance of food gelatins and capsules.

These products carry essential nutrients for the human body.

Food Supplements in Bottles

Consequently, technicians increasingly adopt the use of tablet counters and fillers to optimize the processing of food gelatins and capsules.

· Health care

This another sector that reaps big due to the counting and filling properties.

Most health care products, especially those in bottles such as ointments, require precise filling up to certain degrees and level.

Tablet Drugs in Bottles

With such much-needed precision, which other proper equipment would be suitable?

· Chemical Engineering

Chemistry strictly depends on chemical analysis.

Negligible amounts of elements have a devastating impact on the overall composition of a chemical.

Tablet Chemicals in Bottles

Therefore, you can entirely rely upon this equipment to achieve such a high level of the desired accuracy in filling.

With such information, let’s look at the reasons why you need the Tablet counting and filling machine.

The overall increased demand for the construction of equipment that enhances both the quality and quantity of productions has led to the general rise in varieties of tablet counting and filling machines.

With that in mind, it will be quite challenging to buy an appropriate one.

However, for you to make the right selection, it’s paramount for you to look at the quality specifications of each.

After that, you may pick on the one that adheres to all the necessary set standards.

So, we need to look at the must-have standards for the verification of the authenticity of the machines.

cGMP Tablet Counting and Filling Machine

Check out for the following.

- Machine should be of modular design and the cGMP compliant.

- Look out if the conveyor construction is of the AISI 304.

- Gearbox and motor of the tablet counting and filling machine should be CE Certified.

- Material for the construction of the frame of the machine is that of AISI 304 sheet.

- Noise level production of the machine need to be below 70DB

- All other associated electrical components and electronics should have a CE certificate.

- A fully operational ant dust system.

- The conveyor made of a unique AISI 304 material.

- Well recognized manufacturing company for the Human Machine Interface(HMI) together with control panel.

Types of Tablet Counting and Filling Machine

Of course, you will realize that different variety of tablet counting and filling machines are available.

Knowing all these types is essential for every user not only as a conventional way but also from a technical point of view.

As a result, I will take you through all of them.

Broadly, we can classify this equipment on two bases:

- Operational mode

- Range of model types

What’s the difference?

Let’s dig into that.

· Operational Mode

Well, with the rapidly development pharma technology, we have different types of counting and filling machines.

All of them are classified in accordance with their techniques of operation.

It thus implies, that under the operational mode, we can group them into:

- Fully Automatic

- Semi-automatic

- Manual

tablet counting and filling machine is a mono unit that comprises of several components coordinating together to perform accurate counting and optimum filling.

Above all, all these systems integrate to avail the right productions.

The counter has several parts that potentially vary from a single machine to another.

For the basis of our discussion, we shall focus on the integral sections.

These essential parts are responsible for ensuring an excellent counting and filling process.

Below is a list of the parts:

a. Vibrating feeder

b. Counting system

c. Bottle feeding system

d. Cabinet

e. Control system

Complete Counting, Filling, Capping, Labeling, and Cartoning Line

How Tablet Counters and Fillers Operate?

- Feeding the tablets – Take your batch of pills that you need to count and place them on the hopper.

- At this stage, you need to make some adjustments.

- Adjust the space between the hopper end and the last vibrator, i.e. flat board. You do this depending on the size of your tablets.

- Adjust the conveyor railing and the dropper height according to the bottle diameter together with the height.

- After that, adjust the trailing space. Start by loosening the fixed screw on the bottle feeder. Increase the distance that’s between the two railings on the conveyor preferably approximately 2mm more than the bottle diameter. Eventually, firmly fix the railing.

- Now alter the height of the dropper so that it’s 2mm higher than the bottle height. Use the control knob to do these changes. Usually, the knobs are “Up” and “Down.”

- Finally, tweak the bottle holding bar and ensure that the dropper has a proper fix on top of the bottles.

- The vibration should initiate, and tablets vibrate within the rotating glass disc. Remember that every single disc is capable of counting coated and uncoated tablets, hard/soft capsules.

- The delivery chutes after that direct the tablets from the counting disc into the filling tubes with varied sizes to fit into different containers.

The tablets pass through an infra-red beam as they drop.

These photoelectric sensors count the pills while they fall.

Note that you can preset all these operations of counting, several batches through the PLC and the information should be promptly on display on the HMI.

From this display, you can now monitor the operations.

- Interconnected with a filler just beneath the hopper is a unique dust collector system. The collector enhances a dustless packaging of tablets into the containers.

The extraction makes it easy for capsule counting and pill counting.

Working with counting equipment is way much more comfortable and straightforward.